Toy Design Portfolio

Design first Toys built for play, customization and collectability

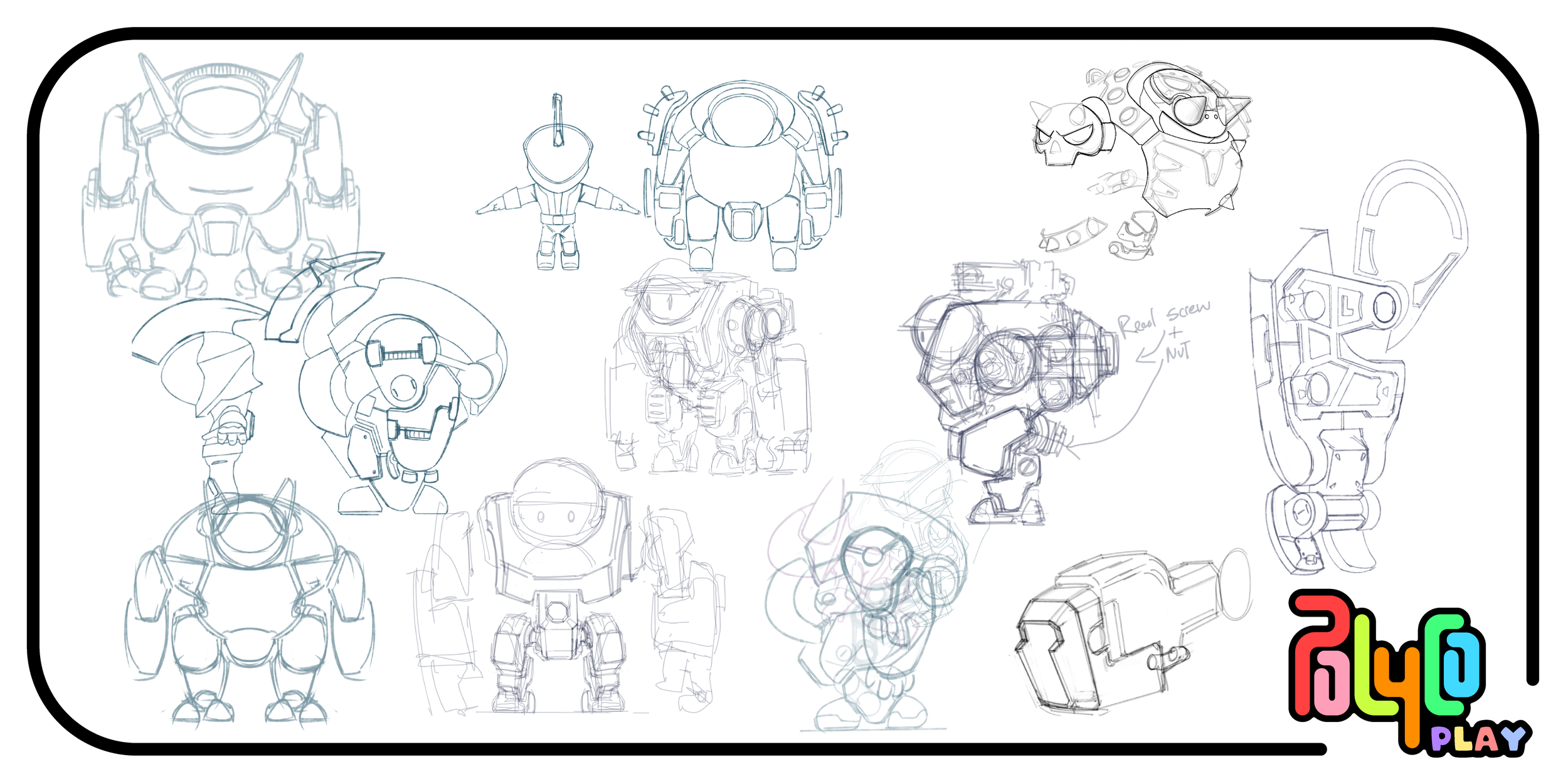

Ideas and Concept

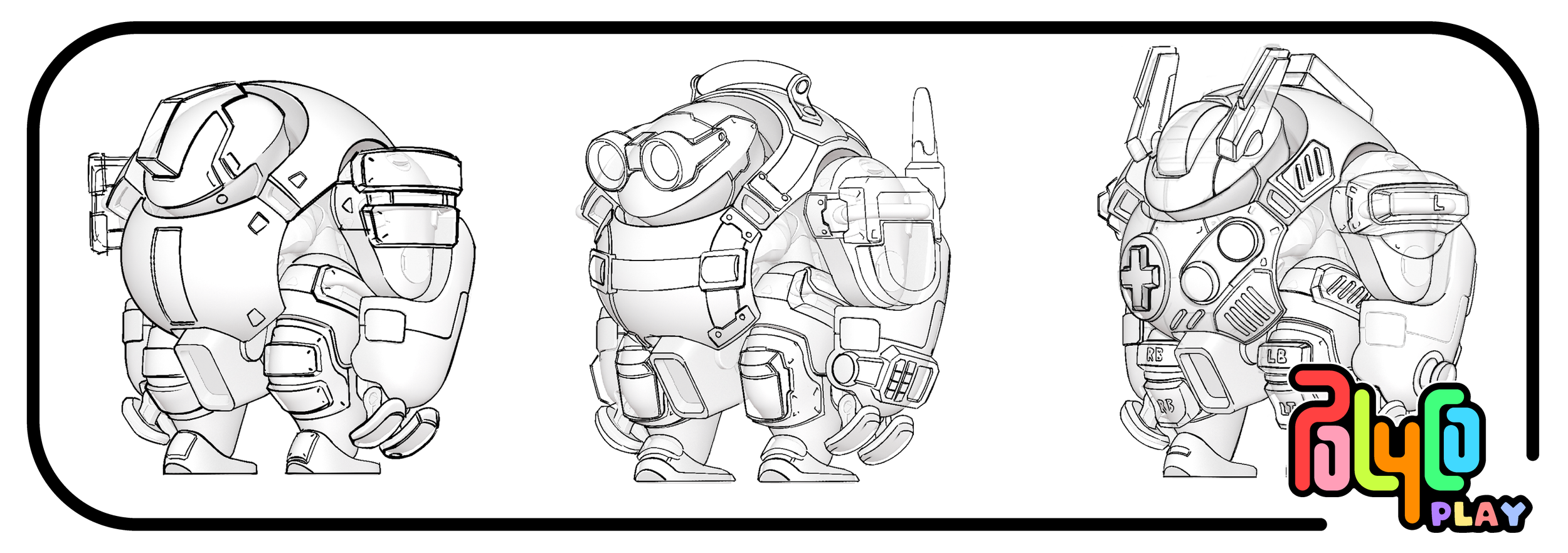

Designed to Scale

The core chassis was intentionally designed to support multiple silhouettes.

By establishing a flexible base structure, the mech can evolve through interchangeable parts, expanding forms, and shifting proportions without breaking visual cohesion. This modular foundation allows each variation to feel distinct while remaining part of the same system.

The result is a design language that stays fresh, adaptable, and scalable over time.

Concept & Design Intent

An articulated mech designed around a detachable pilot system.

The pilot’s helmet is intentionally exposed — not hidden — to make the operator part of the silhouette and visual identity. This creates a clear relationship between machine and character while adding emotional readability to an otherwise mechanical form.

The detachable pilot expands play value, scale contrast, and display flexibility, while the articulation system supports dynamic posing without compromising clean, collectible-friendly proportions.

At its core, the concept explores the balance between armor and identity.

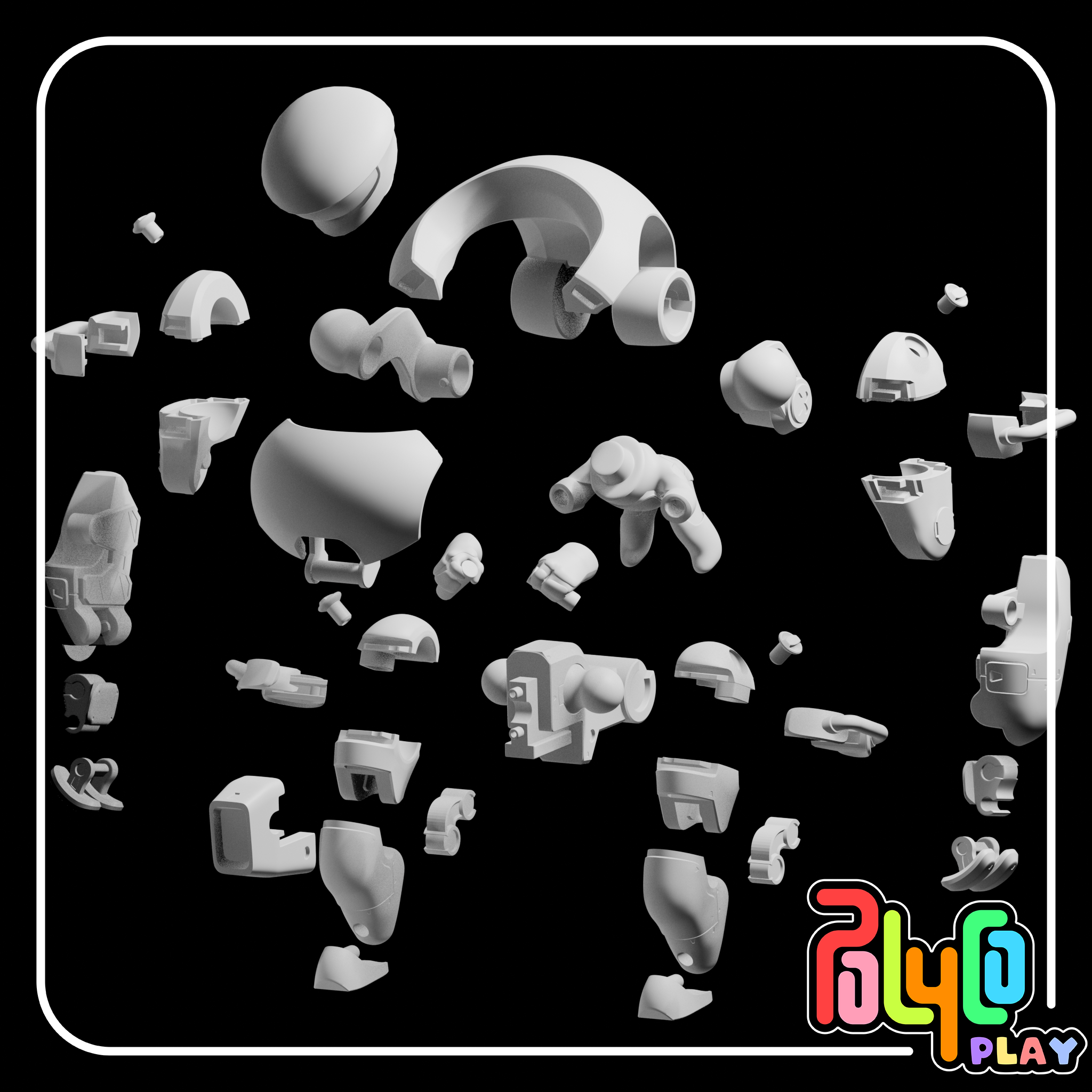

3D Modeling - joint engineering - tolerances

3D Design Process

I begin with silhouette and proportion, establishing a strong base form before adding mechanical detail.

The core is built as a modular platform, with intentional connection points that support articulation, durability, and future variations.

I then refine surface language and test through prototyping to ensure the design works as a physical object—not just a render.

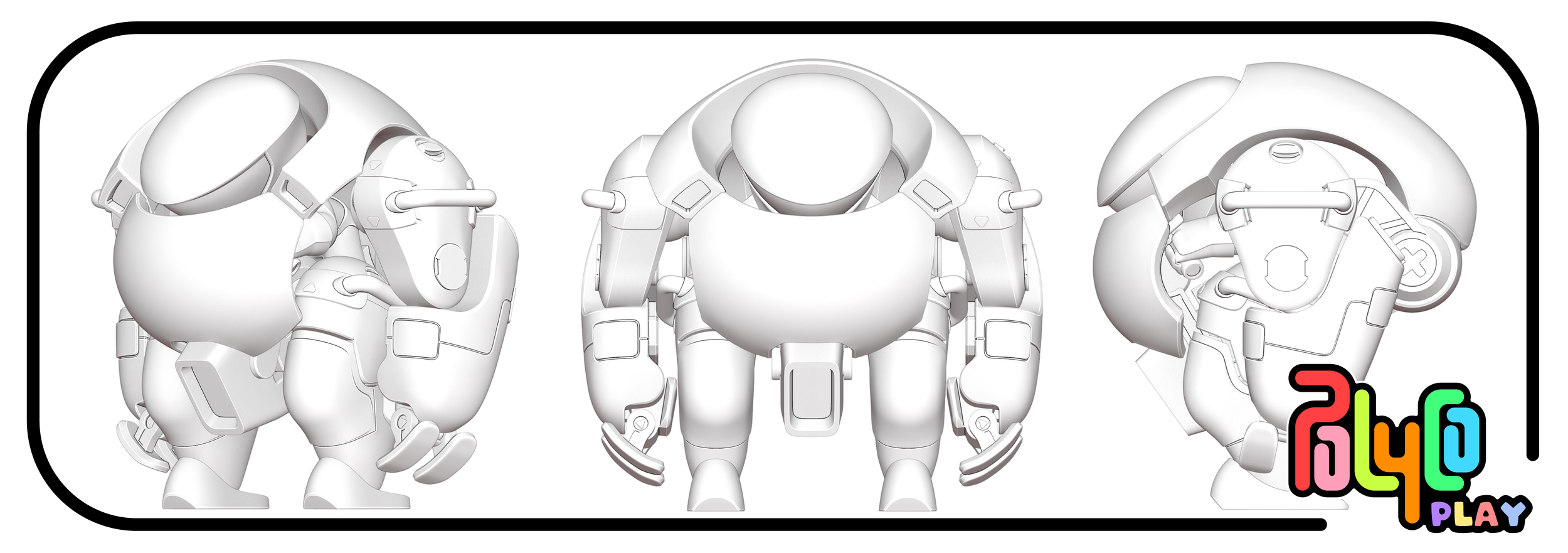

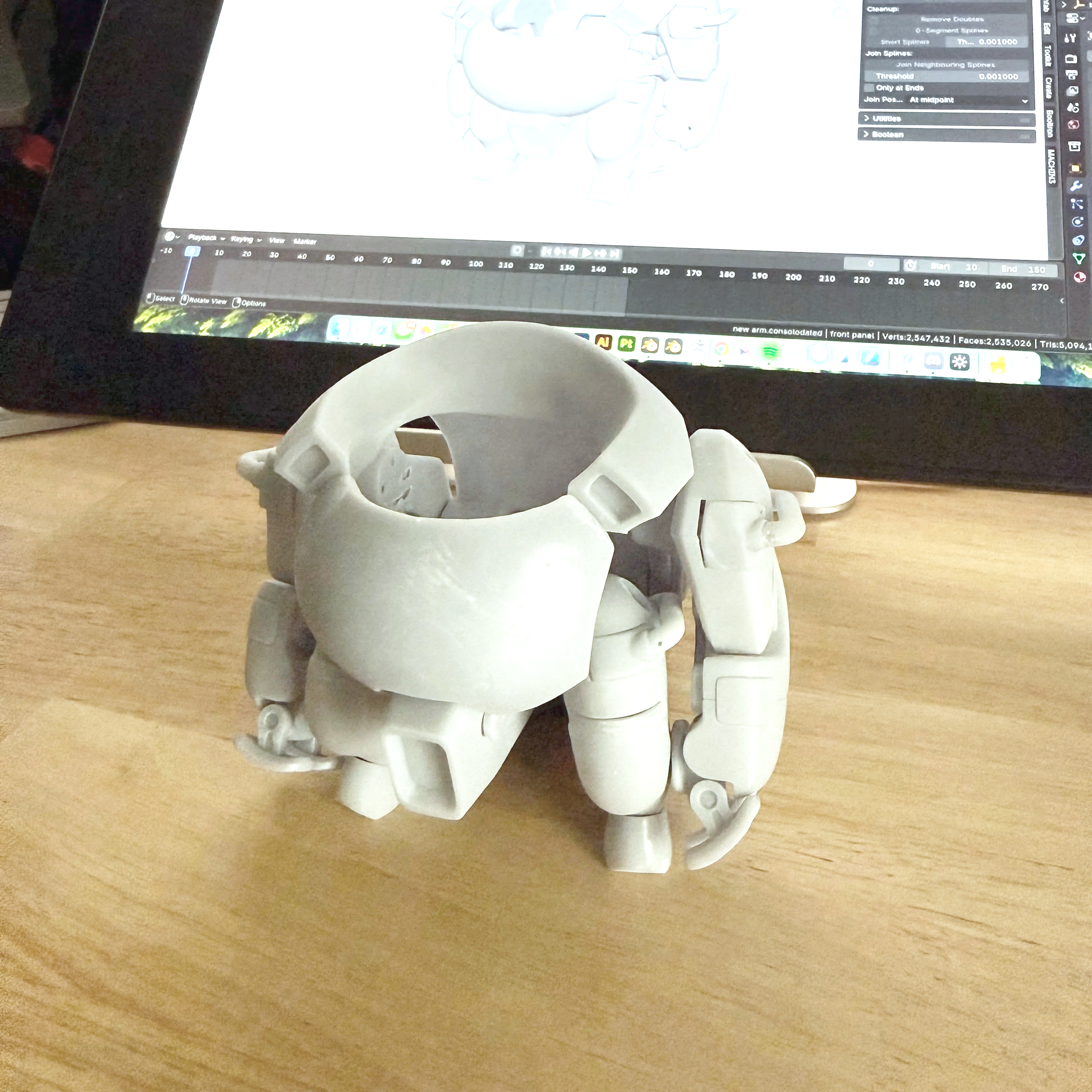

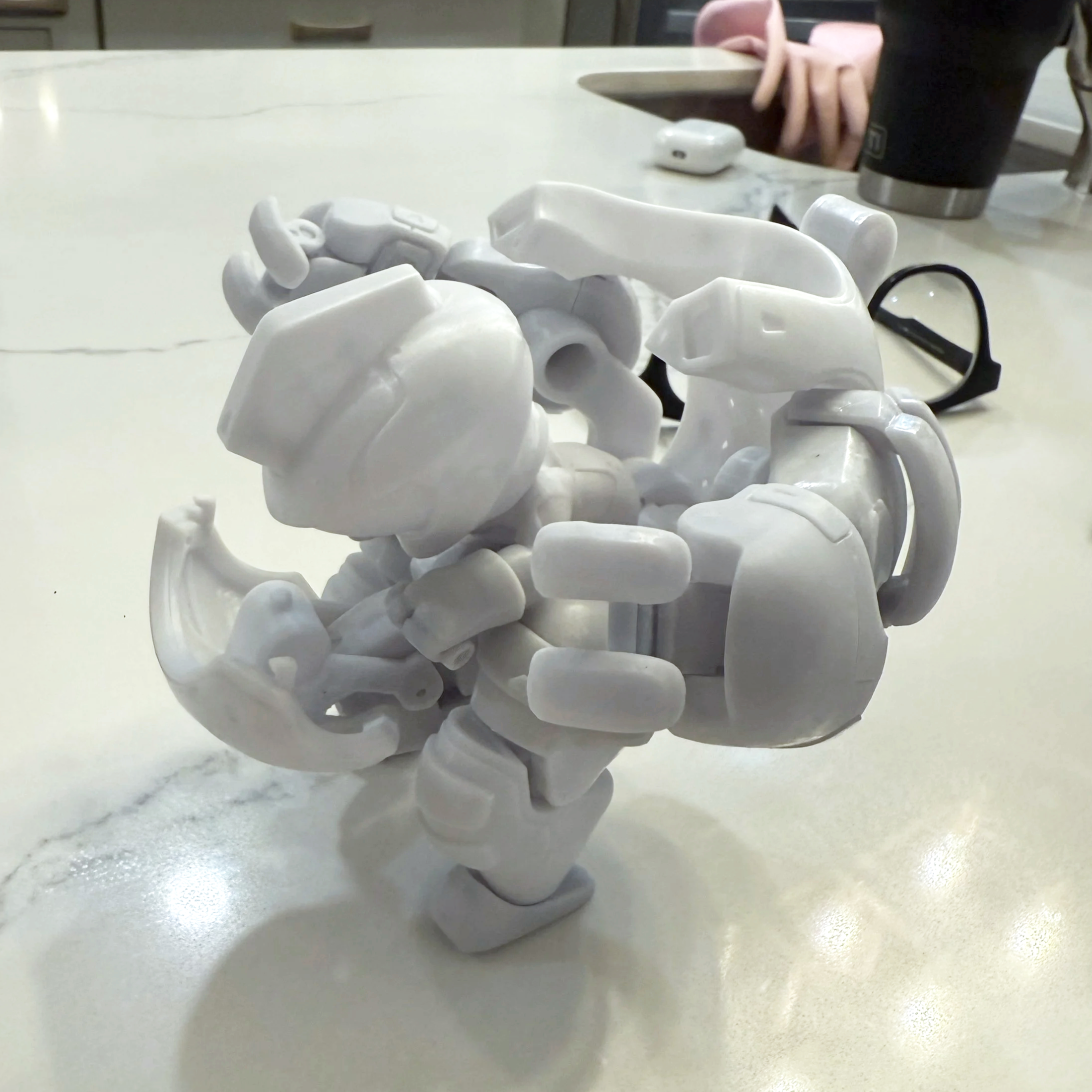

Prototyping and testing

Prototyping & Iteration

Prototyping is where the design proves itself.

I move quickly from digital model to physical test, using 3D prints to evaluate scale, articulation range, connection tolerances, and assembly flow. Seeing the object in-hand reveals proportion shifts and mechanical stress points that renders can’t.

Each iteration refines durability, modular fit, and overall presence—ensuring the final design functions as a toy, not just a concept.

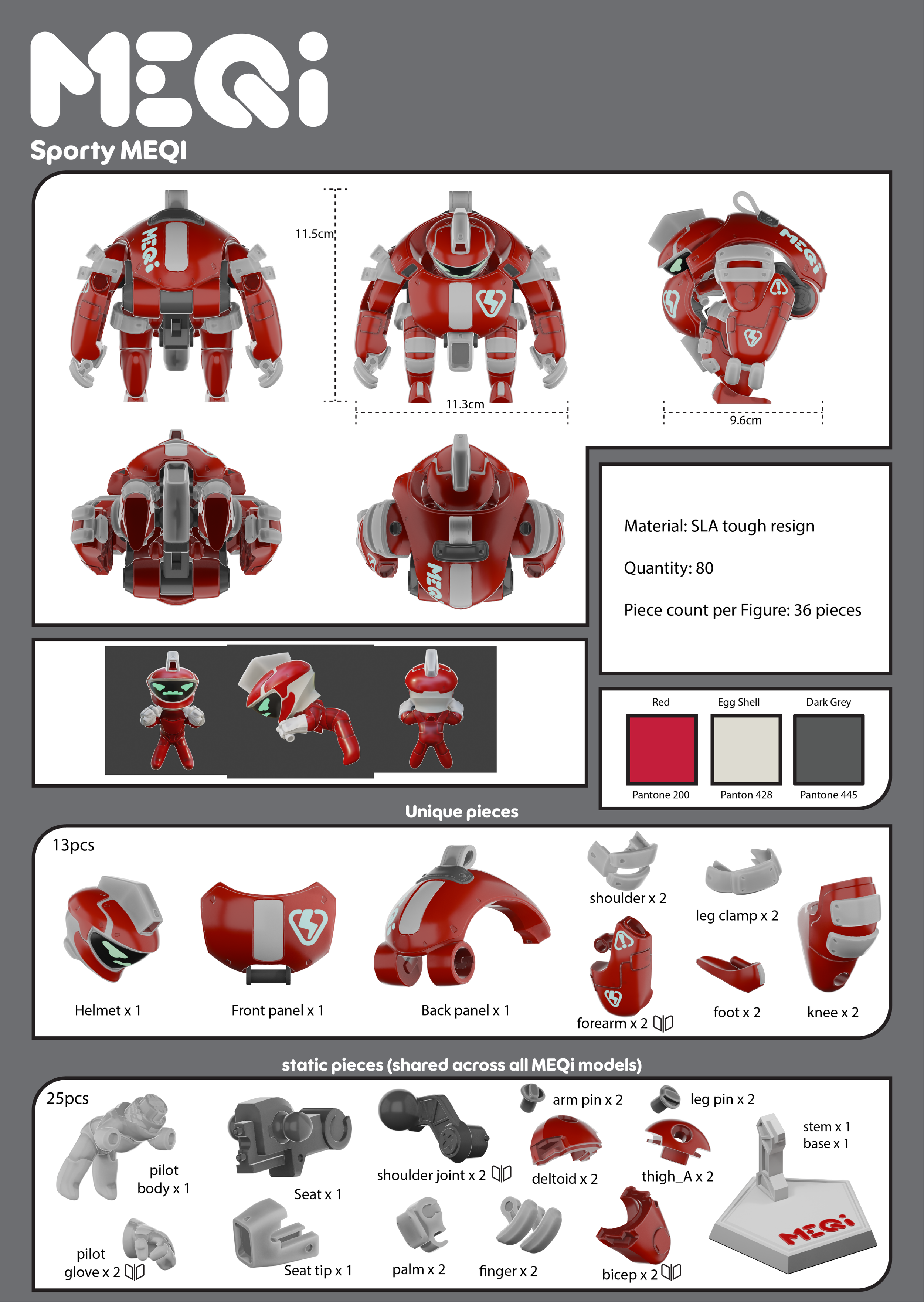

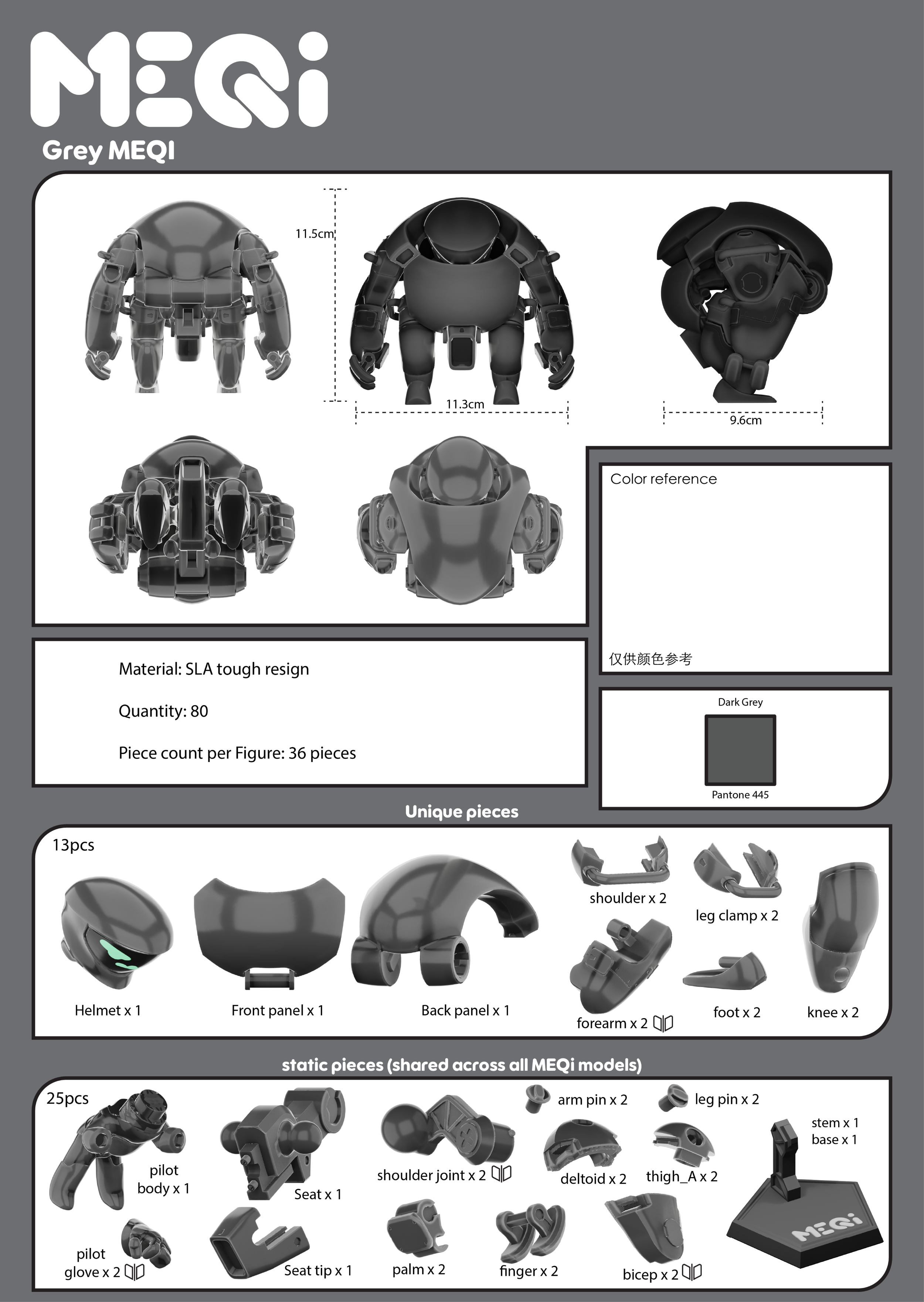

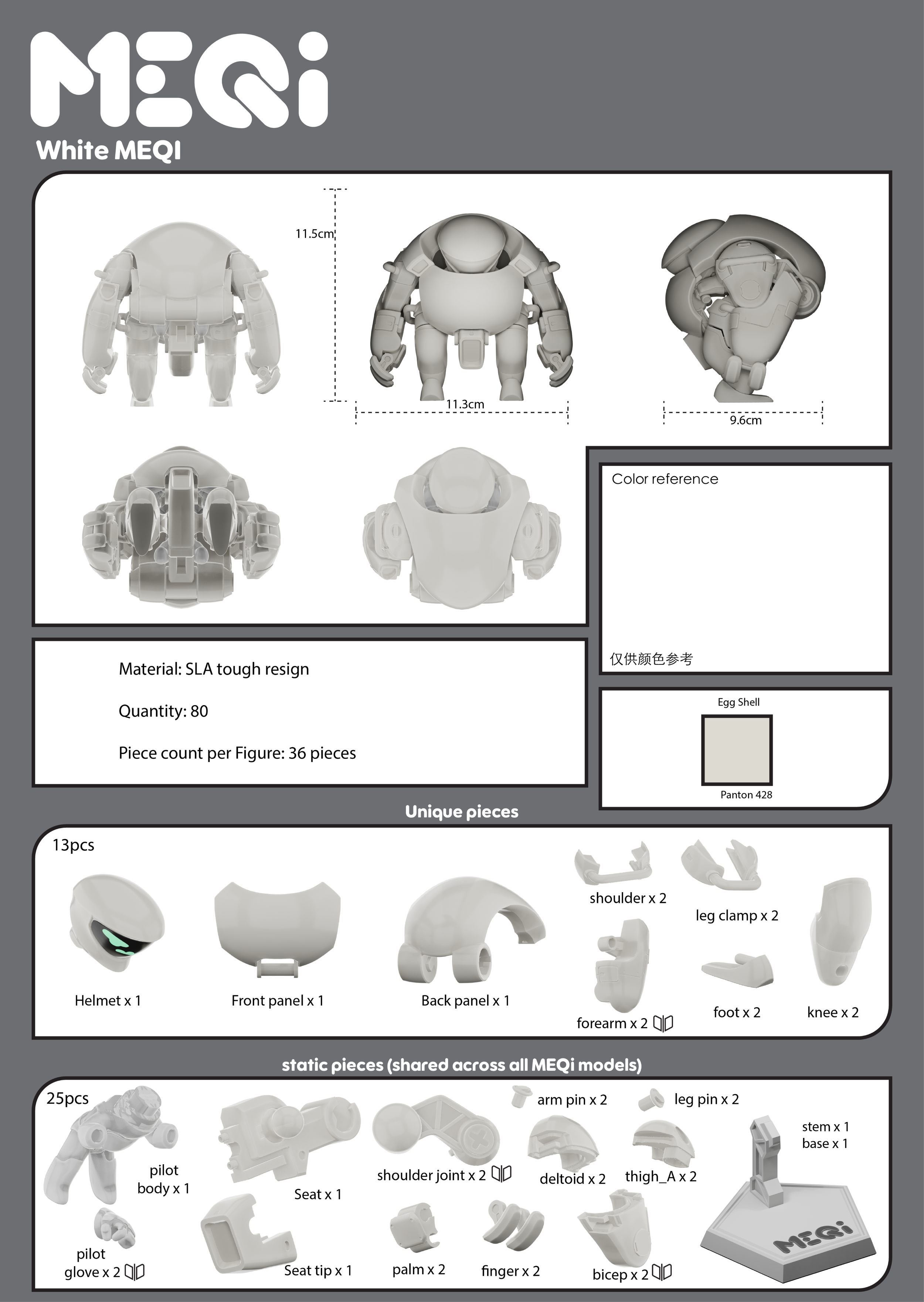

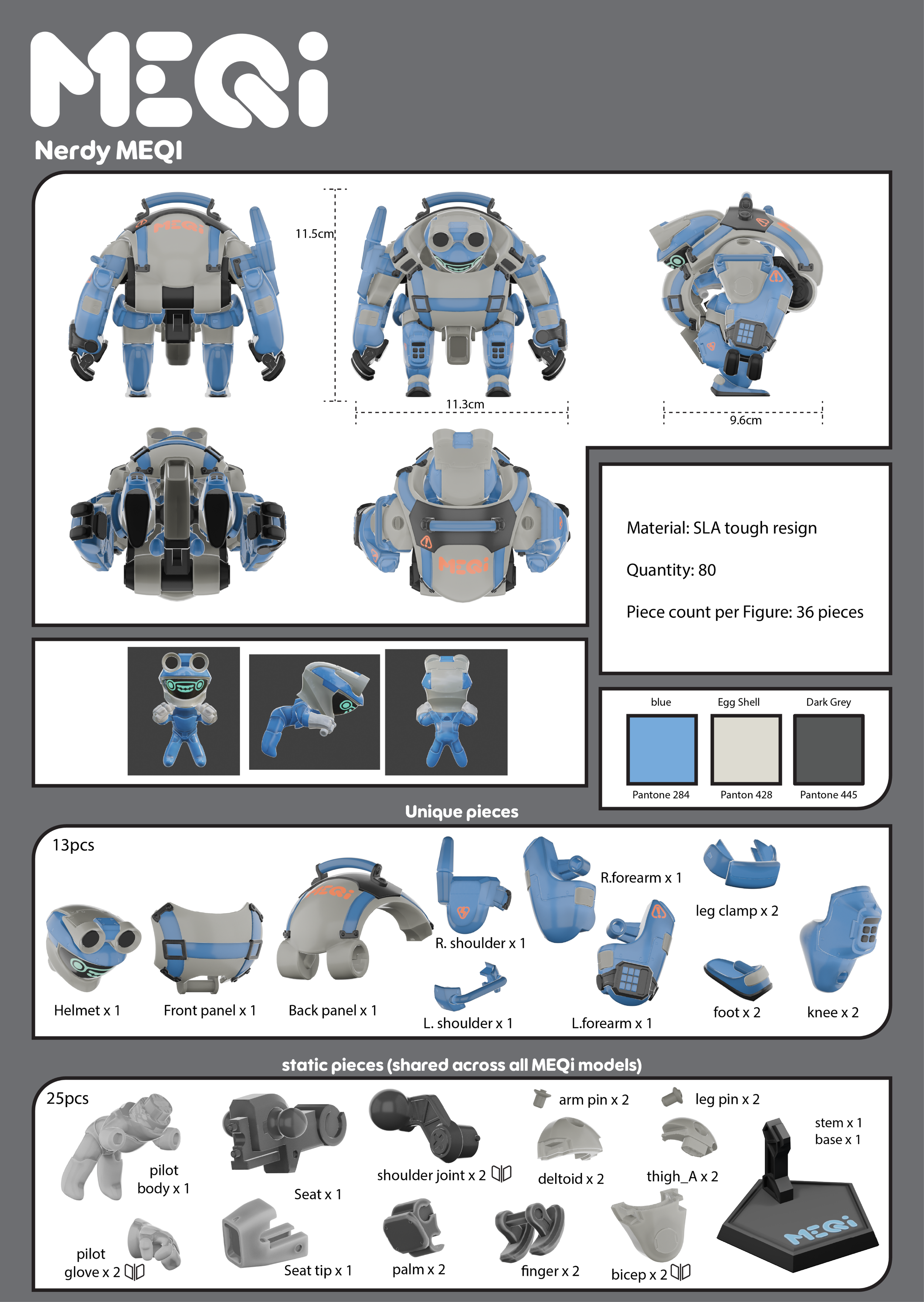

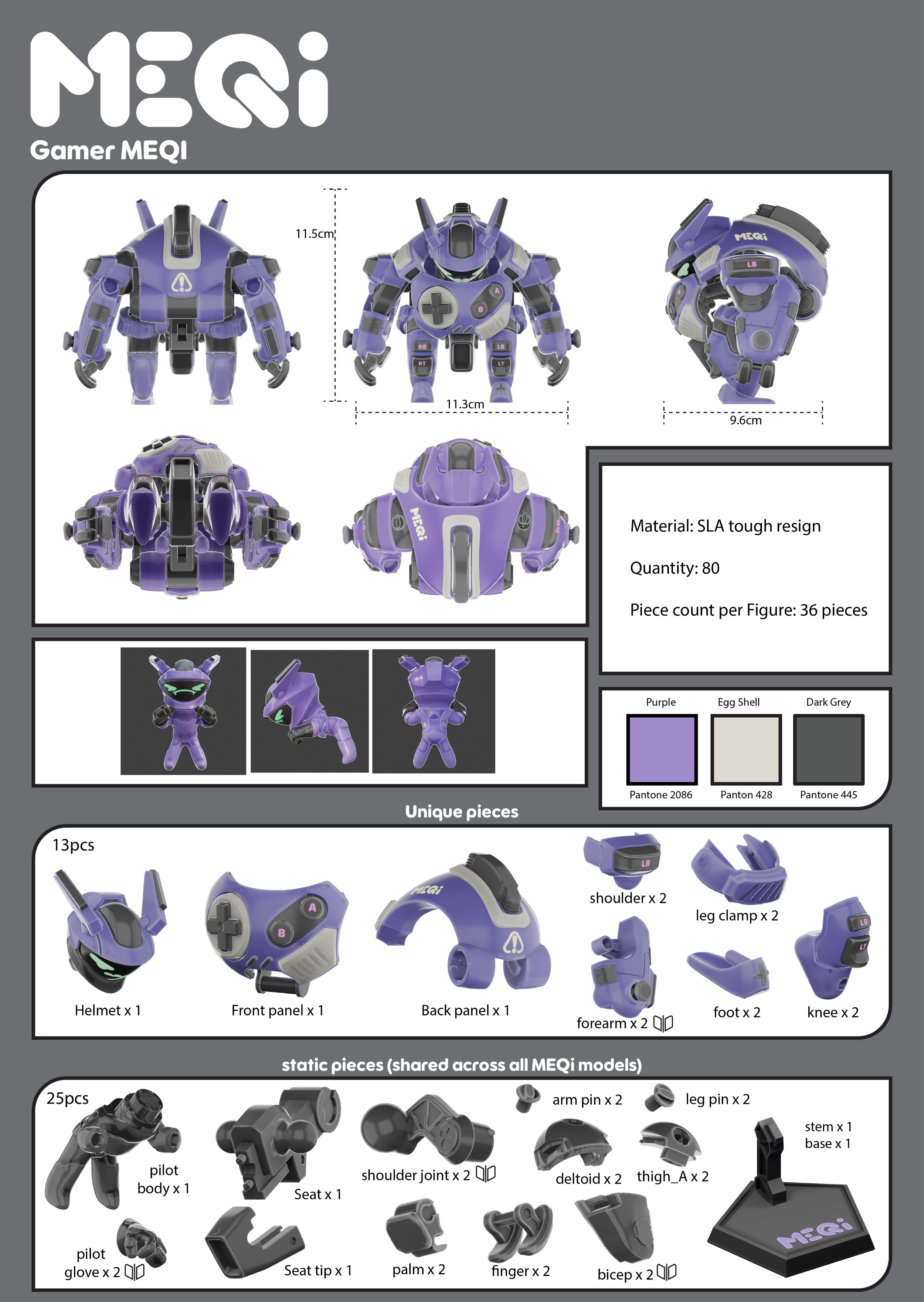

Preproduction and communication with factory

Spec Sheet Development

Spec sheets translate vision into production language.

For each figure, I document part breakdowns, material callouts, color systems, articulation points, and piece counts to ensure clarity across design and manufacturing. Shared components and unique molds are clearly identified to support modular expansion and cost control.

This process aligns creative intent with scalability—ensuring the system can evolve while remaining efficient to produce.

Factory Communication

Clear communication with manufacturing partners is essential to efficient production.

I prepare structured documentation—including spec sheets, part breakdowns, material callouts, and assembly logic—to minimize ambiguity and reduce back-and-forth during sampling. Shared components and unique molds are clearly identified to support cost control and scalability.

This alignment between design and factory ensures smoother sampling cycles, fewer revisions, and a more predictable path to production.

Production

Final Product

A modular, articulated mech system realized through iterative prototyping and production planning.

Distinct silhouettes emerge from a shared core—allowing the line to expand while maintaining visual cohesion.

Designed to evolve.